Top 10 Thermostat Related Problems

- Craig Migliacco

- Mar 31, 2020

- 6 min read

Updated: Nov 20, 2023

Regardless of the type of system or brand of thermostat, it is important to understand that there are many issues that can prevent a thermostat from operating properly. Some problems may seem like common sense while others tend to be a little more complicated. In this article, we will look at 10 thermostat or thermostat wiring problems that can prevent a heater or air conditioning system from working properly.

Problem # 1: Thermostat Location

The placement of a thermostat can have a major impact on whether a thermostat is able to accurately do it's job. For example, you never want to install a thermostat on an exterior wall of the building because of the temperature exchange that occurs with the outside.

Much like exterior walls, installing a thermostat by a window or a door is not ideal because the opening and closing of doors or windows will result in a temperature exchange. Placing a thermostat near a lamp (particularly one with an incandescent bulb) or other appliance/device that emits heat is also not recommended because this heat will affect the thermostat reading. The supply register of the home’s HVAC system is one such device. Kitchens should also be avoided due to the constant temperature exchange from stoves and refrigerators.

The best location for a thermostat is in the middle of the building on an interior wall near a return air grille and away from a corner. This location allows the thermostat to read the temperature of the air flowing through the middle of the building.

Problem # 2: A Loose Connection

(Make sure the power is OFF before adjusting connections.)

A loose connection at the thermostat, furnace, or air handler control board is another problem that may need to be rectified.

Nest thermostats do not use screws to hold the wires in to maintain a connection. As such, even though a wire may appear to be firmly installed, it may not be. It is important to push the wire in all the way and to gently pull on the wire to make sure it is securely connected.

Thermostats that have screw terminals need to be checked to ensure the screws are tightly screwed in so that a good connection is being made with the wires. Use a screwdriver with a wide, non-smooth handle so that you have a good grip and are able to get good torque when turning the screw. You also want the plastic insulation surrounding the wire to be cut back a little bit so you can see exposed copper under the flat part of the terminal. If you don’t, there may not be enough bare copper wire in contact with the terminal to allow for a good connection.

Problem # 3: Powered by Batteries Only

Sometimes a battery-powered thermostat does not correctly indicate that the batteries are low or are not working at all. Low batteries need to be replaced. When replacing batteries in the thermostat, check to make sure the terminals are clean with no corrosion on them. If there is corrosion on the terminals, clean them. Make sure to replace the thermostat batteries at least once a year.

Problem # 4: Problems with a Mercury Thermostat

It is essential that a mercury thermostat is level in order for it to work properly. Other problems could be: the bi-metal section could be out of parameter or the heat anticipator could be set incorrectly. Replacing a mercury thermostat with a digital thermostat is a good option.

Problem # 5: Incorrect Wiring of the Thermostat

The connection of the wiring from the thermostat to the indoor unit control board could be incorrect or a wrong thermostat could be have been installed for the system. It only takes one wire that is incorrectly installed to not allow the system to work properly. This could cause high electricity costs, an uncomfortable temperature in the building, or the system to not work at all.

Problem # 6: The Thermostat Wires Could be Intermittently Touching Each Other or the Ground Frame

Wires could be rubbing against something that causes the insulation to wear away. This can cause a short and the low voltage fuse to pop. This could also cause the system to run when the thermostat is not telling it to. Whenever possible, run wires through rubber inserts so they are not touching any metal.

Also keep in mind, if the insulation on each of the wires at the thermostat are stripped back too far, the wires may touch and cause problems. If the wires in the thermostat are compressed against each other, they may also touch. Try to separate the wires from each other, as much as possible.

Do not staple a thermostat wire in place too tightly or hit the wire with a hammer when trying to secure a staple. Hit the staple in before hand and zip tie the wire to the staple.

Problem # 7: A Nicked or Broken Thermostat Wire

A wire may have been incorrectly stripped of its insulation, resulting in a damaged wire. This could be caused by using an incorrect tool. Don’t twist in a circle to strip wires and don’t use diagonal pliers, instead use wire strippers that are designed to be used on a variety of different wire gauge sizes. Wires can also become damaged over time, through other means. For instance, mice and other rodents may sometimes chew through thermostat wires, particularly when the wires run through a crawl space of a building. Wires can also break or have a bad connection at a wire nut or Spade connector.

Problem # 8: Incorrect Thermostat Program Settings

Incorrect settings in the thermostat can result in the system turning on or off at inappropriate times. The best way to handle these errors are to look up the thermostat model number online for instructions on how to correctly set the thermostat program.

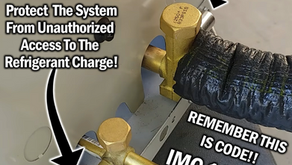

Problem # 9: Cold Air Entering Through a Hole

Cold air may be entering the area where the thermostat is located via a hole in a wall, attic, or crawlspace. This will affect the temperature that the thermostat is sensing. Sealing the hole in the wall where the thermostat is located with silicone will help. Sealing the hole in the attic or crawlspace with fire foam or rock wool insulation will also help. Holes in the attic or crawlspace through the wall plate should be sealed anyway per fire code.

Problem # 10: Thermostat, Control Board, or Other Components are Bad

When troubleshooting, consider the following possible problems:

· The thermostat may be bad.

· The control board may not be sending the voltage to the inducer motor or blower motor.

· The capacitor for the inducer motor may be bad or the inducer motor itself may be bad.

· The capacitor for the blower motor may be bad or the blower motor itself may be bad.

· A relay on the control board may be bad, so the correct voltage isn’t being sent out to components.

Needless to say, many different problems can exist with relation to the thermostat, but getting a clear grasp on what to look for can help equip you to find the most obvious or complex thermostat problems out there. If you are looking for more detail on any of these problems, be sure to check out our Top 10 Thermostat Related Problems! Heat and AC! Video below!

Looking for resources to work on air conditioners and heat pumps? Check out our book “Refrigerant Charging and Service Procedures for Air Conditioning” where we go step by step through procedures such as pressure testing, the vacuum procedure, standing vacuum test, breaking the vacuum with refrigerant as well as other procedures such as recovery and pump downs. Learn to check the charge and to troubleshoot systems. The full outline is available at https://www.acservicetech.com/ac-book along with information on our other products! If you have already purchased our book, be sure to tell local HVACR Instructors about our book and what you think of it. We would love to get the book into the hands of the next generation of HVACR Technicians!

Also make sure to check out our HVAC Quick Reference Cards as well as our Refrigerant Charging Workbook! They are both great resource to give you an advantage out in the field!

Published: 3/31/2019 Author: Craig Migliaccio

About the Author: Craig is the owner of AC Service Tech LLC and the Author of the book “Refrigerant Charging and Service Procedures for Air Conditioning”. Craig is a licensed Teacher of HVACR, Sheet Metal, and Building Maintenance in the State of New Jersey of the USA. He is also an HVACR Contracting Business owner of 15 years and holds an NJ HVACR Master License. Craig creates educational HVACR articles and videos which are posted at https://www.acservicetech.com & https://www.youtube.com/acservicetechchannel

.png)

Thermostat problems like wiring faults or bad placement show why smarter solutions are key. With Smart Home 2025 tech, these issues can be reduced, making homes more efficient and hassle-free.

One of the absolute best dutch oven for bread baking where everything about this enamel cast iron dutch oven is top-notch. This porcelain enamel is a baking in dutch oven guide 5-inch high oven perfect for bread baking and is available in a wide variety of different colors. Its large holding handles and a high-temperature resistant lid cover is proof of its quality and durability. Close your eyes and trust us with this one. You won’t regret buying this dutch oven for bread.